How to insulate a house with polystyrene from the outside - different options, preparation and installation rules

When a building is built, many property owners think about the question of how to insulate the house with polystyrene from the outside.

Thanks to proper insulation, money is saved on coolants consumed in winter; in addition, an insulated building is much cooler in the summer.

According to expert calculations, even the most massive, thickest and most durable walls are almost impossible to completely protect from freezing in winter if the building is not insulated.

Content:

- What material is best to use for wall insulation?

- Calculation of insulation thickness

- Technology for insulating a brick house with polystyrene from the outside

- Mounting on fasteners, adhesive composition, combined version

- Preparing the walls

- Panel installation

- Common mistakes when insulating a house with your own hands

- Insulation of the facade with penoplex, what are the advantages

- Features of internal insulation

What material is best to use for wall insulation?

Today, many different thermal insulation materials are made that are used for insulation.

Here is a list of the most popular and frequently used thermal insulation products:

- polystyrene;

- mineral wool;

- Styrofoam;

- penoizol;

- polyurethane.

These materials are best suited for insulation and are used more often than other products.But which of these insulation products is the best?

It all depends on the individual characteristics of the building. Only experienced, professional specialists will be able to select the most suitable material after carrying out all the calculations and assessing the situation.

Calculation of insulation thickness

To avoid heat loss as much as possible, it is important to correctly calculate the thickness of the insulation boards. But if you choose too thick a material, this will lead to unnecessary material costs, while energy efficiency will not increase. Thanks to the correct calculation of the thermal insulation layer, the house will be warm in winter and cool in summer.

On the Internet resources of many manufacturers of insulation materials there are special online calculators; they make it possible to very easily and quickly read what thickness the thermal insulation should have, and what type of insulation is suitable for a particular situation.

Each insulating material has its own thermal conductivity coefficient. Depending on this coefficient, the required thickness of thermal insulation boards is calculated using the formula; it is influenced by the thickness of the walls, climatic factors and other nuances.

The material from which the house is constructed plays an important role when calculating the thickness of the insulator. Walls made of concrete, brick, hollow blocks and other building materials have different thermal conductivity values; depending on this, the thickness of the thermal insulation is selected.

So, if the thickness of a brick wall is 25 centimeters, then a thermal insulation layer is chosen that is at least 4 centimeters thick.And if the wall thickness is 50 centimeters, then it will be enough to insulate it with polystyrene foam, the thickness of which is 3-5 centimeters, depending on climatic conditions.

Technology for insulating a brick house with polystyrene from the outside

After the optimal insulation material has been selected, it is important to choose the right fastening technology slabs to walls.

Three main methods of attaching panels to the outside of a brick house are used:

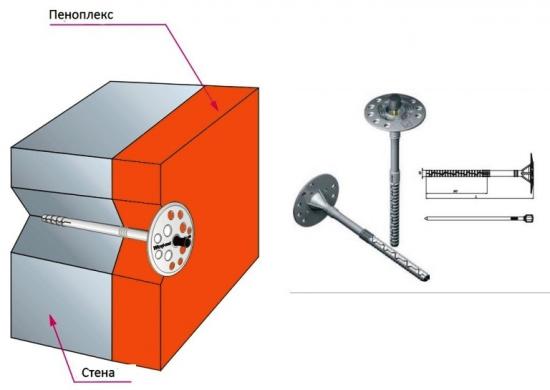

- Using plastic dowels. Each sheet of polystyrene is fixed in at least 5 places with special plastic dowels that have a wide cap, and at the edges these caps overlap the joints of 2 sheets. This is the most complex and time-consuming method, however, it is considered the most reliable.

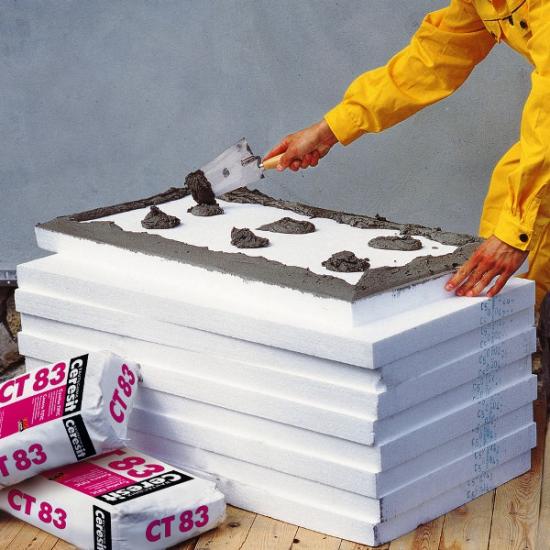

- Using special glue. This technology is used when the walls of a building are leveled as much as possible with plaster or putty and are perfectly smooth. The adhesive composition is applied to the surface of the polystyrene boards, after which the sheets are pressed against the wall with force.

- Combined option. In this case, special glue and dowels with large diameter caps are used. First, the sheets are glued to the wall surface with adhesive, after which they are securely fastened with several plastic dowels.

Which of the above methods to use for each individual case should be decided by experienced specialists.

They will analyze all the parameters and nuances, taking into account the features of the walls and the load that the insulation will exert along with the finishing, and then they will select the most optimal option.

Mounting on fasteners, adhesive composition, combined version

To install insulation sheets onto fasteners, purchase plastic dowels with wide heads.These elements are popularly called umbrellas or fungi. Under each of them, holes are drilled in the wall with a hammer drill, umbrellas are inserted and plastic nails are driven in with a hammer.

To install thermal insulation using an adhesive composition, it is important to choose the right adhesive that is suitable specifically for outdoor work. The composition must be frost-resistant and must be suitable for gluing polystyrene. In the store, be sure to read the instructions for using adhesive products.

The combined option is the most common, as it is the most reliable.

First of all, the polystyrene sheets are fixed with an adhesive solution, and then secured with plastic dowels. In this case, it is important to choose the right glue and the length of the dowels, which should be several centimeters greater than the thickness of the polystyrene.

Preparing the walls

When all consumables and tools are prepared, begin preparing the walls.

Proper preparation includes the following:

- old paints and finishes are removed;

- remove all flaking and crumbling areas;

- remove all facade elements that will interfere with the thermal insulation of the house;

- using putty or cement mortar, cover up cracks, potholes, depressions, seams and other damage, the depth and width of which is more than 5 millimeters;

- Moss, mold, and fungus, if any, are removed from the surface of the walls;

- One or two layers of deep penetration primer are applied. Be sure to prime those areas that are constantly exposed to water and moisture, this includes the foundation and plinth.

When all of the above preparatory work has been completed and the primer has dried, they begin to fix the polystyrene sheets.

Panel installation

Most experts involved in home insulation recommend using a combined installation option for polystyrene panels.

This method is as follows:

- The starting profile is installed at the bottom of the building along the entire perimeter of the house. It is important to install this profile strictly horizontally using a level; all polystyrene sheets will be installed on this profile. The profile is secured with dowels.

- Prepare the adhesive composition according to the instructions given on the packaging.

- Glue is applied over the entire surface of the panels; the thickness of the composition should be from 0.5 to 1 cm. It is important not to waste glue so that the insulation sheets are securely fixed to the wall.

- The first slab from the corner of the house is installed, it is placed on the profile. It is important to press the sheet against the wall so that it is securely fixed.

- Each subsequent sheet is fixed with an adhesive composition, with an indentation of 0.5 cm from the previous panel.

- It is important to place each top panel in a checkerboard pattern; it is necessary to ensure that the seams of the slabs are out of order and do not coincide; gaps of 0.5 cm are left between each subsequent row.

- After gluing each sheet, use a puncher or drill to drill holes through it in the wall at the corners of the slab and in the center. Plastic dowels are inserted into these holes and plastic nails that come with the dowels are driven in. It is important to recess each dowel approximately 1-2 mm into the polystyrene so that later the plastic elements do not interfere with the finishing process.

When all the panels are secured, the seams between them are filled with a sealing compound.

This is the most reliable method of fixing insulation, allowing you to securely attach polystyrene to any type of wall.

We invite you to watch an interesting video about this.How to insulate the outside of a house with polystyrene:

Common mistakes when insulating a house with your own hands

Here is a list of the main mistakes that non-specialists make when insulating houses:

- save on the density and thickness of polystyrene;

- use the wrong adhesive composition;

- choose a cheap mesh and install it incorrectly;

- perform work at too low or, conversely, too high air temperatures;

- insulation is carried out inside the house, not outside;

- do not cover the insulation on top with a reinforcing layer;

- they use extruded polystyrene foam, which is not suitable for façade thermal insulation.

- By avoiding these mistakes, you will definitely be able to properly insulate the building with your own hands.

Let's watch a video analyzing the most common mistakes made when insulating:

Insulation of the facade with penoplex, what are the advantages

Penoplex is well suited for thermal insulation of walls; this material has the following advantages:

- long service life;

- small weight;

- practical waste-free;

- does not ignite;

- low moisture absorption;

- low water vapor permeability;

- Fungi and mold do not grow.

In addition, penoplex has a minimal heat conductivity rate, so it is often used during insulation.

Features of internal insulation

Experienced specialists do not recommend insulating houses with polystyrene foam or polystyrene from the inside, since condensation forms under the slabs, as a result of which mold and fungi develop. Internal insulation reduces the area of the room and shifts the dew point, as a result of which the thermal insulation properties of the walls decrease.

If the owner nevertheless decides to install heat-insulating sheets inside the room, then he must use a technology identical to external insulation.

So, following the recommendations and advice from this article, you can successfully insulate the outside of your house using polystyrene sheets. But if you do not have the necessary skills and experience in this area, it is better to entrust the work to qualified specialists.

Comments

Polystyrene for insulating the facades of a house should be taken with a density of at least 25 and a thickness of at least 50 mm. With a smaller thickness, the insulation effect will be noticeable, rather weak. For passive houses, in general, the insulation thickness is 200 - 250 mm.

Once upon a time we simply tried to insulate the walls of the house with polystyrene foam, the foam simply did not stick to the walls properly, the walls must be perfectly flat, which is a problem for many.

For a similar task inside and outside the house, I would prefer penoplex with a thickness of 50mm to ordinary porous synthetic material, which rodents manage to destroy. And you still need to pay special attention to waterproofing.