How to make artificial stone, from what materials, how to use it

When decorating a house, the question often arises about what materials to use to decorate the facade; the idea often comes to use stone.

But difficulties can arise with natural finishing: the heavy finishing material puts a significant load on the walls and is relatively difficult to work with.

But don’t give up on the idea, because the real mineral can be replaced. To do this, you should learn how to make artificial stone yourself. This process is quite exciting and creative.

Content:

- What is artificial stone

- How to make artificial stone from gypsum

- Artificial stone without shapes: cheap and beautiful

- Stone made of concrete and facade plaster

- How to make an artificial stone from paper

- Do-it-yourself artificial stone made of polystyrene foam

- What is artificial stone for countertops made from?

- How to use cheap artificial stone made by yourself in the interior of a country house

- Application in landscape design

What is artificial stone

Stone decor is made from different materials. The choice of raw materials is also influenced by the location of application. For example, cement analogs are more often used for facade work, while gypsum and foam plastic will be relevant for the interior.

The cost of artificial stone is significantly lower than natural stone. Moreover, you can experiment and create it yourself.

A beginner or a child can handle the process of making this decorative element. The main condition for success is a high-quality form that does not break after several pours. Reliable material for it is made of silicone or polyurethane.

How to make artificial stone from gypsum

It is quite easy to create an imitation stone finish from gypsum. There is a high probability that you will be able to do it the first time.

You need to prepare:

- molds;

- gypsum;

- screwdriver;

- bucket;

- scales;

- spatula narrow 10 cm and wide 40 cm;

- water;

- spray;

- scoop;

- measuring cup;

- soap.

Containers for shaping the product are made by hand; you can also purchase ready-made ones. If you choose in a store, it is better to give preference to the material polyurethane - it is quite durable, each mold will allow you to make many blanks.

A bucket is needed for mixing the material. It is advisable to take an old one or one made of silicone, which is easy to clean.

Any plaster that is available in a hardware store will do. The packaging may say g-6 or g-16. These numbers indicate the density of the substance. G-16 is a durable mineral, products made from it are almost impossible to break.

You can use less durable G-6 gypsum for finishing a house and apartment, but for public places you can use stronger material. You will also need to take care of the higher strength of the workpieces if they are planned to be transported. This will eliminate the threat of destruction from increased loads.

Before pouring the plaster into the molds, they must be moistened with a soap solution made from water and laundry soap, so that it is easier to remove the dried blanks later. The forms must be placed on a flat surface.Then spray each with soapy water from a spray bottle.

To obtain a high-quality gypsum mixture for work, it is recommended to mix: 1 kilogram of gypsum g-6 with 1 liter of water. For 1 square meter it takes from 5 to 10 kilograms of gypsum.

Creation stages:

- After the water is poured into the bucket, you need to take a screwdriver, put an attachment on it, similar to a mixer attachment, and lower it into the bucket. Gradually add plaster from the second container to avoid excess lumps.

- Fill the bottom of each mold, then spread the remaining plaster with a spatula. After 2 minutes, you can use the spatula again to level the swelling plaster.

- After 20 minutes you can remove the fragments from the molds. You need to pull the mold by the edge so that it separates from the plaster. You can also turn the finished stone over and remove it.

- After removal, the gypsum fragments must be dried in the sun or a special dryer must be made if a lot of decor has been made.

Artificial stone without shapes: cheap and beautiful

You can make decorative finishing without using molds. This method is very simple, despite this the stones turn out beautiful and original. To create a natural effect, you need to make a stencil.

You can draw the stencil yourself. To do this, you can take unnecessary oilcloth, a large sheet of paper or cardboard. Next, draw out the expected dimensions of the stone.

Decorative material manufacturing process:

- Mix the gypsum in a silicone container. If there is no such bucket, then you can place a garbage bag in any container and after finishing the work you can throw it away, without soiling the bucket with plaster.

- The stencil must be covered with transparent oilcloth before you begin to form the stones. Distribute the solution over the oilcloth using a spatula.

- Give the plaster surface the desired relief using small and large spatulas.

- Divide the fragments according to the markings. Now you need to wait until the plaster hardens, 15-20 minutes.

- Dry the finished cast products in the sun throughout the day.

Let's watch an interesting video:

Stone made of concrete and facade plaster

This method is considered one of the most common - simple and practical. Facade plaster produces a plastic mortar that can be used to imitate almost any stone texture.

Cement-gypsum plaster is intended for finishing the external parts of buildings.

Among its components:

- sand,

- small crushed stone,

- marble chips,

- rounded granules.

Stages of applying plaster to create stones:

- A thin layer of plaster 3 millimeters thick is applied to the prepared walls. You should not wait until it is completely dry.

- The next layer is applied with a spatula - you need to make spots by trimming the coating.

- Now you need to smooth out the relief with a spatula. The tool is pressed tightly against the solution, so as to make wide, ragged spots, between which there are rough areas.

- Allow the finish to dry for 5 minutes. Then paint the decor with acrylic paint or Venetian plaster.

- At the last stage, polishing is done using special wax for decorative plaster. Then wipe the wall with a dry cloth for a polishing effect. The imitation of a smooth stone wall is ready.

About making stone from concrete and facade plaster, watch the video^

How to make an artificial stone from paper

This option is considered simple and affordable. Such masonry is relevant for interior spaces, as well as for masking uneven walls.To imitate natural masonry, simple cardboard from boxes or corrugated cardboard is suitable.

You will also need materials and tools:

- Titan glue;

- scissors;

- knife;

- PVA glue;

- brush;

- tissues or toilet paper;

- egg trays;

- acrylic paints;

- acrylic lacquer;

- acrylic putty.

Manufacturing process:

- Cut the cardboard into strips that will be equal to the size of the pebbles.

- Cut the egg trays into pieces, while maintaining the uneven texture of their surface.

- Cover the cardboard strip with these pieces. You can use Titan glue - it dries quickly. Using pieces from trays, make an imitation of relief on a strip of cardboard.

- In order to smooth the surface of the brick, it should be greased with PVA glue and a paper handkerchief should be glued on.

- Do the same with other parts. When the blanks are dry, cover them with a layer of acrylic putty. Let dry.

- Paint the bricks with acrylic paint to make them more realistic.

- Glue the products onto the prepared surface and cover with three layers of varnish.

Do-it-yourself artificial stone made of polystyrene foam

Their polystyrene foam is an original imitation of its natural counterpart. This material can be used to finish the external foundation.

In order to make such stones yourself, you need the following tools:

- Styrofoam;

- putty knife;

- foam glue;

- acrylic paints;

- primer;

- large palette knife.

Step-by-step production of foam stones:

Make notches on the prepared surface for better bonding of materials. Prime the wall.

Dilute tile adhesive and apply it to the surface. Glue pieces of foam plastic (the size is not important, since the relief will be formed by applying the solution).

Apply a layer of tile adhesive to the glued foam. Using a palette knife, make smooth and convex areas.

The texture can also be formed with a spatula by making notches on the solution.

After the layer of sand-cement glue has dried, you can paint the decorative material with dark brown acrylic paint. Pebbles can also be tinted with white and ocher.

Another option for making stone from foam plastic, watch the video:

What is artificial stone for countertops made from?

Products made from non-natural material are of good quality and have a long service life. If a tabletop is made from them, it will not only be original, but also durable.

The artificial material is not saturated with excess moisture, does not evaporate harmful substances, and is environmentally friendly. In terms of weight, such a countertop will be lighter compared to one made of real stone. Also, harmful bacteria will not be able to take root on it.

There are many design variations of artificial stone countertops. They can be of different textures, colors, and shape variations. The most common artificial materials for the manufacture of countertops: agglomerates - stones made from marble or acrylic chips, quartz sand, coloring pigments, limestone.

Artificial quartz is a moisture-resistant material. In terms of strength, it is second only to diamonds and topaz. Acrylic stone is less durable, but it is easy to process and not heavy in weight. It is advisable not to place hot dishes on acrylic surfaces.

How to use cheap artificial stone made by yourself in the interior of a country house

The decorative mineral is considered an excellent substitute for its natural, expensive analogue in the design of summer cottages.It can be used for finishing facade and interior walls and as decorations in the garden.

This version of the material is much more convenient than natural material, which requires strengthening the walls before laying it.

Even in wooden houses, such a finishing element will look very organic. Window sills made of unnatural stone are characterized by increased strength. If you plan to decorate a house made of plaster, it is worth considering that during cold weather this material can deteriorate.

For a dacha, the most suitable strong material is concrete. It costs a little more than gypsum, but is stronger and more resistant to sudden temperature changes.

Artificial stone will be an ideal budget option for a summer house - be it finishing window sills or facing a fireplace. Using such material you can be sure of its strength and reliability.

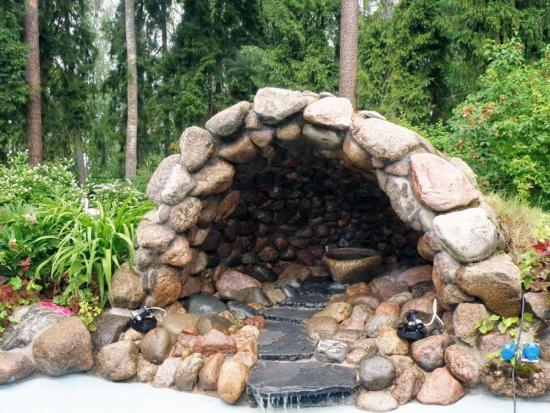

Application in landscape design

Artificial stone is often used in landscape design. To create an aesthetically pleasing picture, stonework is decorated artificial reservoirs, fountains, paths. In combination with green trees and shrubs, the masonry looks natural, and gray colors come to life in their own way.

Today, stone is widely used in the design of a garden, summer cottage or gazebo, and it is no longer possible to imagine a design without it. Paths decorated with this material look more aesthetically pleasing than those made of concrete.

This material is more wear-resistant. At the same time, the surface of the artificial one is smoother. There is also a large selection of sizes, shapes and colors of artificial stone, so it can be matched to any landscape design.

Artificial stone is considered one of the promising materials for interior decoration of buildings and landscape design.

In addition, this material is affordable and acceptable for those who do not have the opportunity to make a design from a natural analogue.

In appearance it is almost indistinguishable from the real thing, and in some respects this material is even better.

Comments

Such a stone is very convenient to use for exterior and interior decoration of a house, or you can use such a stone to lay a beautiful path on the site. There are a lot of ideas, and the price won’t be expensive!

In my opinion, for finishing the interior walls of a house, artificial stone made from gypsum is best suited, only it should be made in special polyurethane forms.

The price of the molds, in my opinion, is somewhat overpriced, and for the sake of a few squares of imitation torn stone for interior decoration, it’s definitely not worth buying them, but if someone decides to decorate the basement of a large house, then it’s worth carefully calculating the costs.