Mineral fertilizer spreader, advantages, how to make it yourself

To get a good harvest, you need to regularly add mineral fertilizers and fertilizers to the soil. They will help saturate the soil with useful elements that are necessary to increase fertility, which contributes to high yields.

Large farms with a lot of land use professional equipment, and on a summer cottage or personal plot, a manual device designed for spreading fertilizers is quite sufficient.

Content:

- Fertilizer spreaders, their purpose

- Types of fertilizer spreaders

- Operating principle of spreaders

- What are the advantages and disadvantages

- How to make a manual mineral fertilizer spreader with your own hands

- Making a homemade organic fertilizer spreader

Fertilizer spreaders, their purpose

Mineral fertilizer spreaders are presented as additional attachments, the use of which significantly speeds up the process of fertilizing the soil or sowing seeds.

Similar devices are:

- mounted

- trailed

Sometimes spreaders are used to add sand to the soil or to spread it in winter during icy conditions. Such equipment provides high efficiency for any type of use.

Some of the models are heavy and capable of performing various functions. These types of spreaders are irreplaceable.

Spreaders provide precise dosage and uniform distribution of mineral mixtures over the surface of the cultivated areas, which contributes to positive results during the cultivation of agricultural products.

The use of this type of equipment reduces the cost of purchasing the required nutritional supplements.

Some of the spreaders are attached to agricultural machinery using special attachments. This type of technology helps to enrich the soil with minerals using the scattering method.

Types of fertilizer spreaders

Units for applying fertilizers can be:

- trailed

- mounted

- disk

- pendulum

Agricultural equipment for applying mineral fertilizers may have additional functions. They can mix, grind, transport.

They are usually divided into 4 main groups.

Trailed

Such devices have high productivity in distributing micronutrients and sowing seeds with minimal pressure.

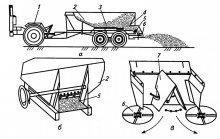

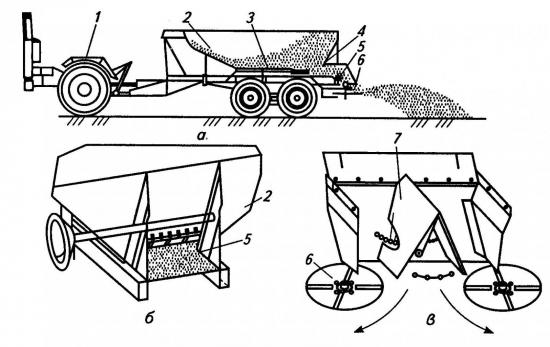

The device includes a body, a conveyor, a dispenser, and a drive. To control seeding, it is necessary to change the speed of the conveyor and the size of the gap, which is why a damper is needed.

The most common are towed devices. In appearance they resemble a trailer. For this reason they received this name. Only the accuracy of fertilizer distribution is not at the highest level.

Mounted

This type of spreader can be as powerful as a tractor. The device consists of a frame, a device for attaching to a tractor and a hopper. In addition, there are safety grilles that prevent large elements from getting inside the unit.

At the bottom of the equipment there are special funnels designed for spreading mineral mixtures.

A distinctive feature of any of the mounted devices is the presence of distribution disks. In case of malfunction, they can be replaced.

During operation of the unit, fertilizers are supplied via a shaft to the surface of the distribution discs from the hopper.

The discs rotate in opposite directions, which promotes uniform distribution of fertilizer over the treated surface.

Disk

This type of spreader is equipped with special discs and blades made of stainless steel and a cardan shaft. To regulate the amount of fertilizer spread, there are special dampers that can be controlled directly from the tractor cabin.

By changing their position, the amount of distribution of nutritional supplements over the field surface is controlled. In order to prevent mineral additives from clumping and large particles from entering the device, it is equipped with stirrers and special nets.

Pendulum

This type of spreader is produced only by foreign companies. For this reason, they have rather low demand on the Russian agricultural market.

The main working body of this installation is not rotating disks, but a special tube that makes reciprocating movements from side to side - it swings.

To ensure durability and long-term performance, this part is made of high quality plastic. Thanks to a special shaft, the tube makes reciprocating movements.

Still, it should be noted that this type of spreader is inferior to disk spreaders.In addition, they make quite a lot of noise and unevenly distribute nutrient mixtures over the surface of the land.

Operating principle of spreaders

Fertilizers are poured through protective grids into a hopper, inside of which there is a tedder. It ensures a uniform supply of granules to the valves. Then they fall on the surface of the spreading discs, on which there are special blades that capture the granules.

Under the influence of centrifugal force, mineral substances are scattered over the surface of the treated area.

The additional ability to adjust the location of the blades ensures uniform distribution of nutrients across the entire width of the gripping surface.

To select a specific position, the seeding rate, the characteristics of the fertilizer used and the speed at which the tractor moves when applying fertilizer are taken into account. The unit is driven by a power take-off shaft.

What are the advantages and disadvantages

Any technique has its advantages and disadvantages. The main advantages are:

- fast delivery of nutrients;

- the ability to process large areas;

- time efficiency;

- uniform coverage of the surface of the site with fertilizers;

- the composition is added only while the device is moving;

- some models have the function of regulating the amount of mixtures added;

- Possibility of use for other agricultural purposes.

The main disadvantage is the fairly high cost of the equipment. Summer residents and landowners who use relatively small plots of land make spreaders for applying fertilizers themselves.

To process large areas, you need to buy professional equipment from a specialized store. A wide range of presented models allows you to choose the best option that is suitable for a specific area.

How to make a manual mineral fertilizer spreader with your own hands

The manual device needs to be pushed across the field independently, and this is not very convenient. Nevertheless, it is quite possible to do it yourself. The basis of the device is a pair of running wheels and a box for nutritional mixtures.

11 holes are drilled in the bottom of the box and covered with plates that rotate. A pair of ejectors are installed above the plates.

In addition, you can connect a turner. During movement, the wheels transmit torque to the plates, ejector shaft and agitator.

With this design, fertilizers fall from the box onto rotating plates and then relatively evenly onto the ground.

Making a homemade organic fertilizer spreader

There are two simple devices for applying liquid organic fertilizers that can be successfully used in a country house or garden. The devices consist of an axle, two wheels and a handle. Differences in fertilizer containers.

A plastic bottle, with a capacity of five liters, with a liquid nutritional mixture is suspended from the handle of the device, so that it is at a distance from the ground.

A pair of tubes are threaded through the bottle cap: a long one and a short one; before starting work, you need to blow through the short one so that the liquid fertilizer fills the long tube. Then the liquid flows by gravity.

Bend a metal pipe with a diameter of 24 millimeters on a special machine. The bottom of the tube is the axis.It has wheels installed.

The wheel located on the right side is fixed using washers and cotter pins on both sides. The left wheel is secured with cotter pins, the right bracket support ring, a washer and a plug.

The distance between the wheels is 70 centimeters. Holes with a diameter of 2 millimeters are drilled every 2 centimeters.

Another device is designed for applying powder or granular fertilizer. The plywood box is filled with a nutrient mixture. A through axis passes through the side walls of the box. It has wheels on it.

Inside the box there are 4 blades on the axis. They rotate with the axle when the wheels move and serve as a kind of agitator. 26 holes with a diameter of 8 millimeters are drilled in the bottom of the box. The same number of holes are drilled in the metal plate, only their diameter is 6 millimeters.

The location of the holes in the bottom of the box and on the plate must match. The plate moves along the bottom of the box left and right by 4 millimeters. The position of the plate is fixed with a special lever.

By moving the lever you can close and open the holes. When they are open and the device moves, fertilizer pours out of the holes.

You can learn more about a homemade fertilizer spreader by watching the video: